Most delays, errors, and fulfillment headaches aren’t caused by people, but by outdated processes. A proper warehouse management system (WMS) doesn’t just track your stock, it helps your team move faster, make fewer mistakes, and actually keep up with busy sales periods without burning out.

This article walks you through four key WMS features that make a real difference in day-to-day operations:

-

How wave picking saves time by grouping similar orders

-

Why barcode scanning prevents packing errors

-

How real-time inventory tracking keeps you from overselling

-

And how automated alerts help fix problems before they turn into complaints

If you’re managing orders across multiple platforms or preparing for another peak season, these are the tools that keep things running smoothly, without adding stress to your team.

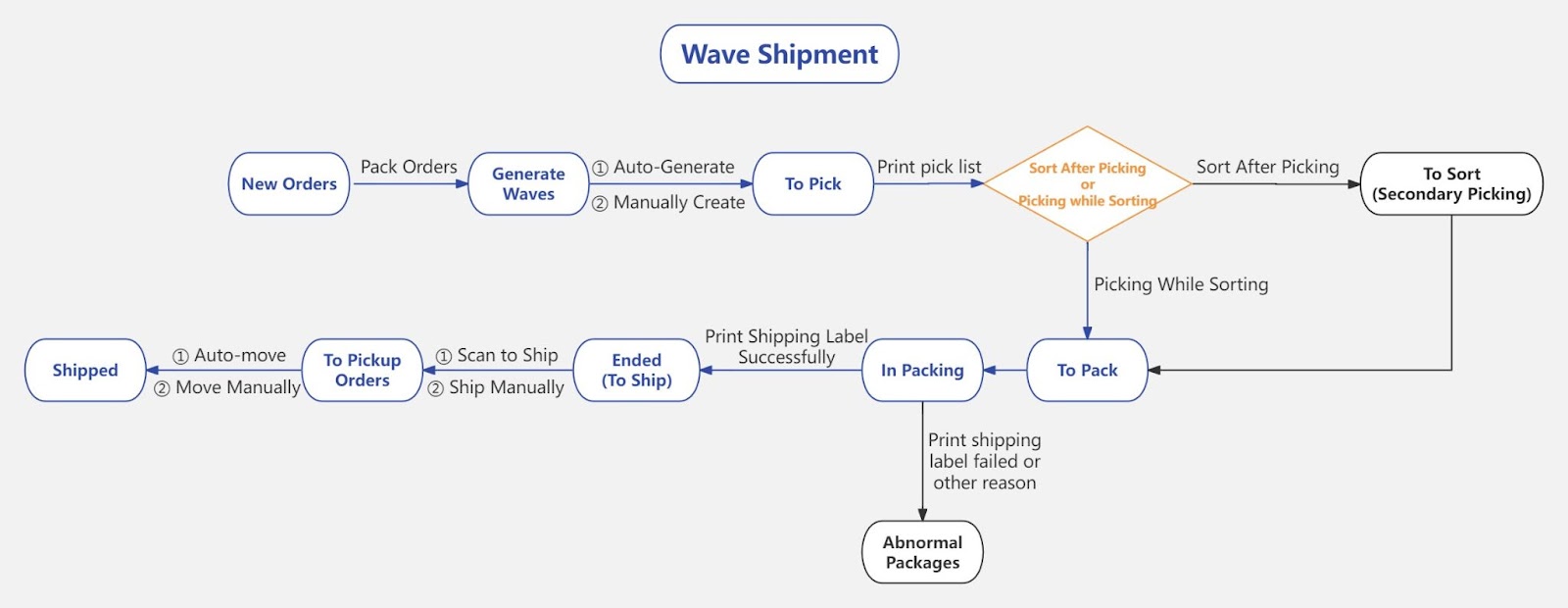

Wave Picking for Maximum Efficiency

Wave picking is a method used in warehouse operations to speed up order fulfillment. Instead of picking orders one by one, which takes more time and effort, a warehouse management system (WMS) can group similar orders into “waves” so your team can pick them all at once, more efficiently. Here’s how it helps:

-

Orders are grouped based on smart criteria, like shipping destination, item type, or order urgency. This prevents your staff from walking back and forth across the warehouse for each individual order.

-

Wave lists are generated, showing pickers exactly which items to collect and from where. For example, if multiple orders include the same item, the system tells you to grab all of them in one trip.

-

Secondary picking breaks large waves into smaller tasks, allowing multiple staff to work on the same batch. This keeps things organised and reduces the chance of error.

-

Urgent or high-priority orders can be picked first, using wave settings to make sure express shipments are always handled on time.

By organising orders into logical groups and providing clear picking instructions, wave picking:

-

Cuts down unnecessary walking

-

Speeds up the picking process

-

Helps staff stay focused and accurate

-

Improves overall coordination on the warehouse floor

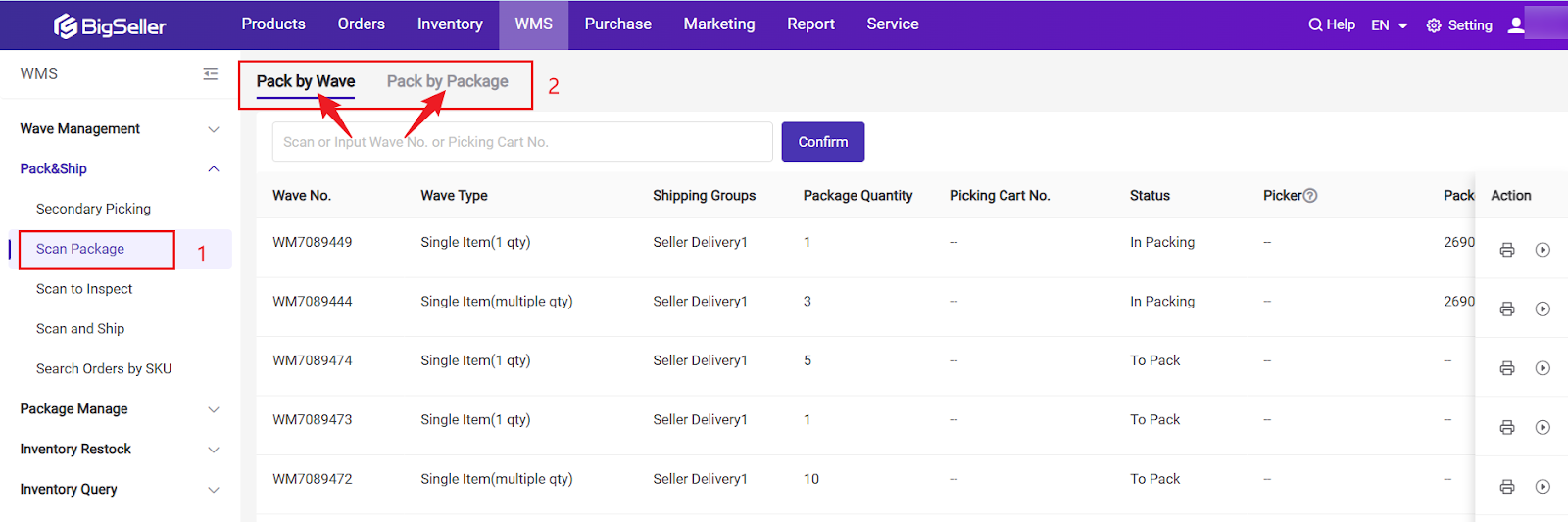

Scan-Based Operations for Accuracy

Manual work in a warehouse like picking the wrong item, packing it in the wrong box, or sticking on the wrong shipping label can easily lead to delayed deliveries and unhappy customers. These mistakes also hurt your seller rating, especially on marketplaces like Shopee, Lazada, or TikTok Shop where penalties can apply.

A scan-based WMS workflow helps avoid these problems by guiding your staff through each step with barcode scanning. Instead of relying on memory or printed lists, warehouse staff scan items and packages at key stages to make sure everything matches. Here’s how scanning improves accuracy:

-

Scan to inspect: Before packing, the staff scans the item to make sure it matches the order. If the wrong item is picked, the system alerts them immediately.

-

Scan to ship: When a parcel is ready to ship, scanning the order confirms that it’s paired with the correct shipping label and courier. This prevents mix-ups at dispatch.

-

Scan package: This final scan checks if the package was already scanned or missed. It helps catch duplicate or missing shipments before they leave the warehouse.

-

Search by SKU or package number: If a problem occurs (e.g. a customer asks where their order is), staff can quickly find the order or package in the system just by scanning or entering the SKU or package code.

This resulted in:

-

Fewer mistakes in picking, packing, and shipping

-

Better tracking of inventory movement

-

Faster and more confident shipment processing

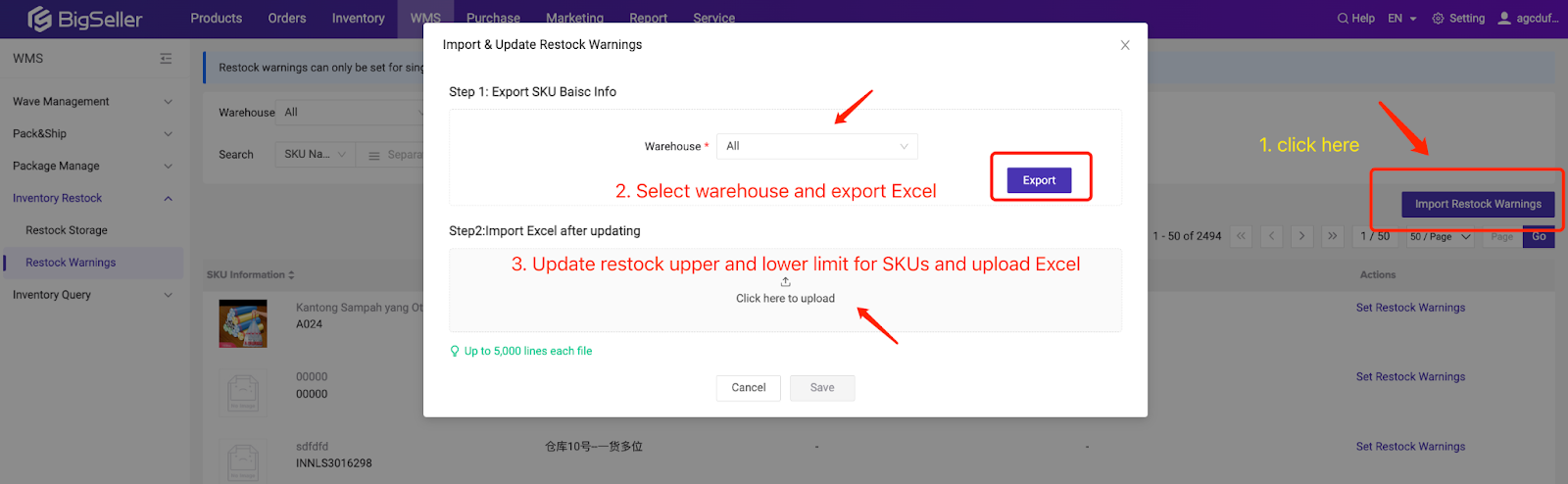

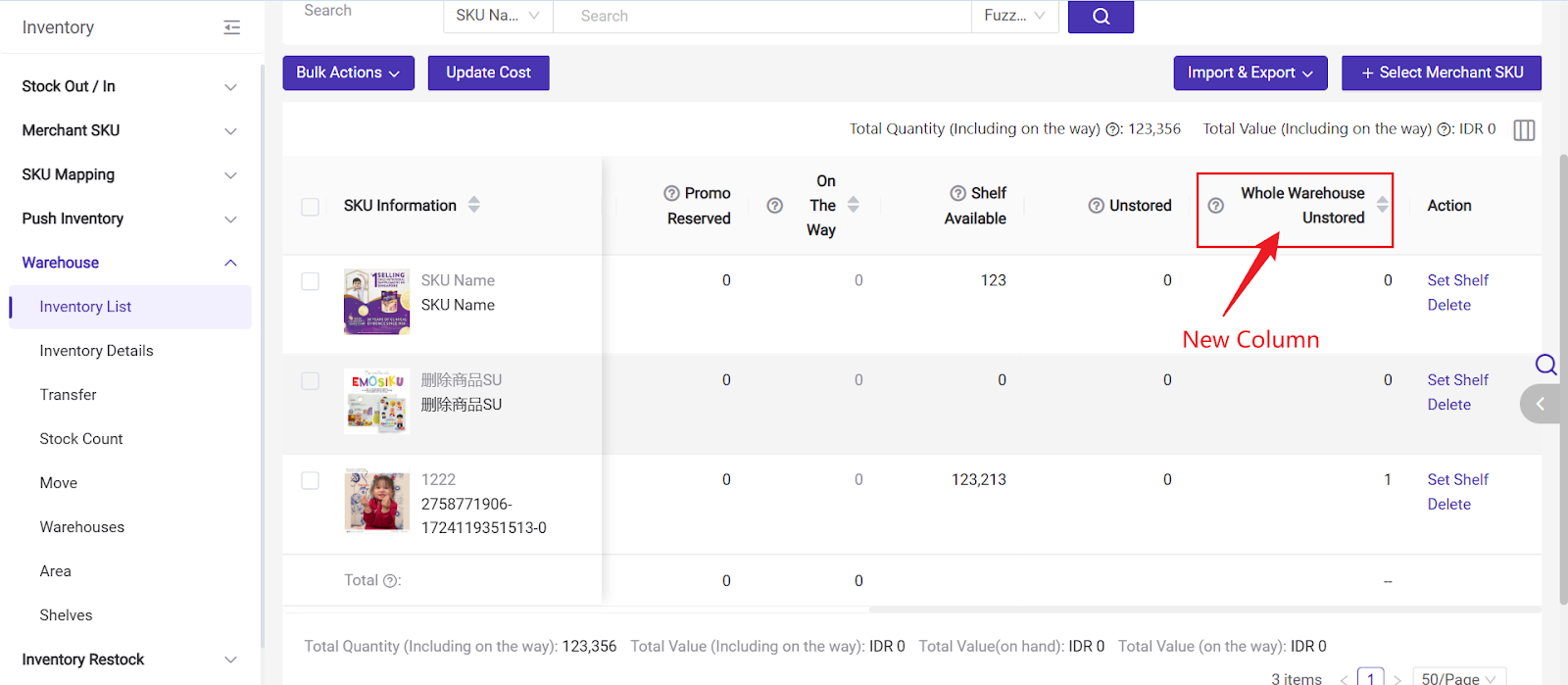

Real-Time Inventory Control

A good WMS keeps your inventory data updated in real time. That means every time an item is picked for an order, moved to a new location, or restocked, the system automatically records it, so you always know exactly how much stock you have and where it is.

This real-time visibility helps you stay in control, especially when you're handling large volumes or selling across multiple platforms. Here’s how it works in practice:

-

Inventory details: You can view accurate stock levels for every SKU across different storage areas. No more guessing or checking manually.

-

Area stock movement tracking: The system shows what products are being moved, picked, or replenished and from which shelf or zone. This helps you detect unusual activity or bottlenecks.

-

Restock warnings: When a popular item is running low, the system alerts you in advance so you can restock before it runs out.

-

Restock storage workflows: You can assign replenishment tasks to staff directly through the system, ensuring the right products are moved to the right shelves at the right time.

The result: You avoid stockouts, prevent overselling, and keep your fulfillment operations running smoothly, even during big sales or peak seasons.

Automated Stock Alerts Prevent Delays

In any warehouse operation, small issues like missing items, scanning mistakes, or delays are bound to happen. The key is catching them early and fixing them fast, before they affect customer deliveries.

A well-designed WMS helps by detecting problems in real time and guiding your team to take the right actions. Here’s how it helps:

-

Abnormal packages: The system flags parcels that might have issues like missing items, scanning errors, or delays so your team can inspect and correct them before they ship out.

-

To ship queue: This shows orders that are packed but not yet shipped. You can quickly spot any hold-ups and prioritise those orders to stay on schedule.

-

Shelf out of stock detection: If a picker scans a location and there’s no stock, the system alerts them and suggests an alternate location (if available), preventing delays and idle time.

The result: You minimise disruptions, fix fulfillment issues faster, and keep operations running smoothly even during peak sales or high-pressure periods.

When Your Warehouse Flows Better, Everything Else Follows

Running a warehouse doesn’t have to feel like a constant race against time (and errors). BigSeller’s Warehouse Management System (WMS) is designed to help Malaysian sellers manage growing order volumes without the usual chaos. Whether you’re fulfilling orders from Shopee, Lazada, TikTok Shop, or all three, BigSeller gives you the structure, automation, and visibility to scale with confidence.

Ready to level up your fulfillment process? Sign up for a free BigSeller account today and see how much smoother things can run!

Stay updated on new features and seller tips by joining our Whatsapp Channel.